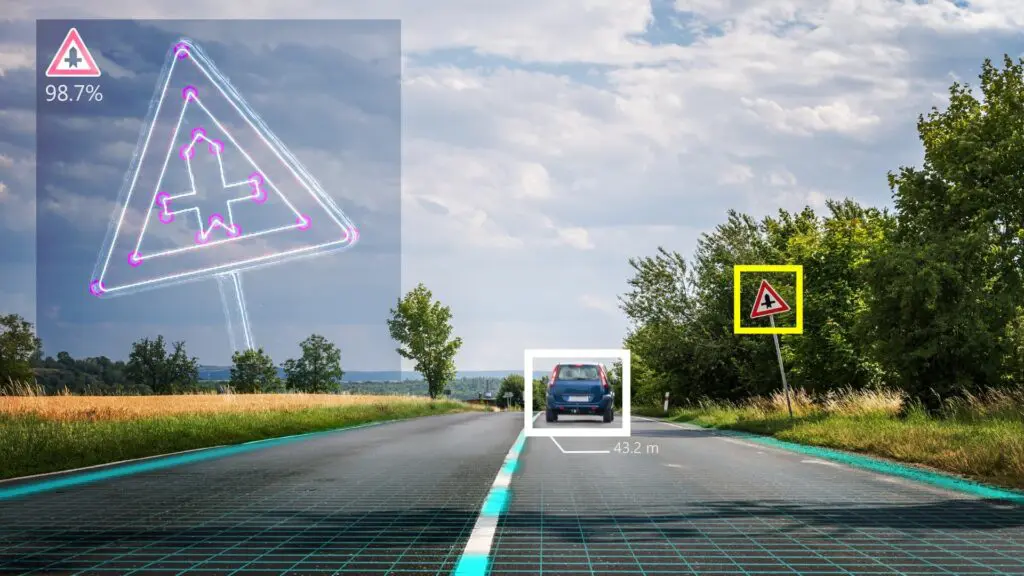

Computer vision (CV) and machine vision (MV) are forms of artificial intelligence that record and interpret visual input. People often use the terms interchangeably. Understandable, because the techniques overlap considerably. For example, image recognition is an important shared feature.

In both CV and MV, the system uses images to analyse and ensure that users can act accordingly. And all this with a speed and accuracy that the human eye and brain can never match. In this article, we look at applications of this technology in the manufacturing industry.

The difference between computer vision and machine vision

The difference between the two is not so much in the technology, but in the application of technology. Computer vision focuses on picking up and processing images. The focus here is on image recognition and providing useful observations.

Machine vision actually stems from this - as a subcategory of computer vision - with the technology being used in an industrial environment. Although the boundary is vague, computer vision can therefore be defined as a technique built to automate image recognition. MV can then be characterised as the application of this technique in the 'real world'.

Machine vision: computer vision in the manufacturing industry

Machine vision is invaluable for optimising all possible production objectives, such as quality, cost and speed. For example, you can use machine vision to inspect products for defects or damage.

Sometimes these deviations are so small that not only do computers detect them faster than humans, but humans could never make the same observation. MV is therefore a powerful tool in automating, optimising and speeding up the manufacturing process.

User cases: 3 examples

Of course, this all sounds very nice in theory, but it only really comes to life when you understand what form computer vision takes in the manufacturing industry. That is why we have listed three appealing examples for you. They are examples that every entrepreneur who deals with a production line on a daily basis can identify with.

Please note that these are only examples for inspiration. Experts all over the world are working hard day in and day out to develop these techniques. As a result, the end of what is possible with computer vision in the manufacturing industry is not yet in sight.

Example 1: Collecting products and parts

Another machine vision solution secures the quality standard of industrial companies of both the products that roll off the conveyor belt and the parts they use. For example, the solution has a machine that can see whether bottles (e.g. beer bottles) are all right and are being packaged correctly.

The machine can even tell if the label was printed on the right quality paper and attached in the right way. An enormous boost in quality assurance, increasing productivity and reducing the number of returns.

So this piece of MV technology even relieves the pressure on the customer service areas of the company.

More on: Image recognition: from the early days of technology to endless business applications today.

Example 2: Application in the pharmaceutical industry

Of course, it is ultimately important for every company that their products are of excellent quality. But you can probably imagine that it is extra important for pharmaceutical companies that each package contains the right number of pills and that all those pills are also completely intact.

After all, you can't have a pill arriving at the user's home accidentally turned out slightly larger or broken into several pieces. The pills must all be exactly the same size, otherwise the user cannot determine the correct dosage.

The pills must also be delivered in exactly the right number, otherwise the user may suddenly run out at a critical moment. When it comes to medication, small mistakes like this are a matter of health and sometimes even of life and death.

Removing non-perfect pills

A specifically applied machine vision technique makes it possible to take pictures of the pills as they move through the production line. A computer analyses and processes these photos and checks whether all pills are the right colour, length and width and whether they are completely flawless.

The computer then indicates which containers contain defective tablets. These containers are automatically removed from the production line. This prevents annoying errors with an efficiency and accuracy that cannot be matched by human labour.

Example 3: Preventive maintenance of production line

If you have a company in the manufacturing industry, then you are extremely dependent on all kinds of physical components. Think of both the parts you make products from and the parts of the collection of machines that makes up the production line.

The parts of those machines need regular maintenance to function properly. Parts that are serviced too late can break down and bring the entire production to a halt.

Repair before it is broken

Machine vision allows you to monitor machines in your production line much better, part by part. Sensors collect data and are able to pick out the signals that indicate a possible future defect.

If the technology detects such a signal, it immediately initiates the necessary actions. In this way, the machine vision technology ensures that the component that poses a risk to the smooth running of the production process is quickly returned to its optimum condition.

Automating preventive maintenance with the help of MV can save your company a lot of money. Just imagine how much money is lost in a large company if the production line is down for just a few minutes.

Data is key

It is important to keep in mind that machine vision can only make a difference in your business if you have clear goals. Then you need to 'train' the machine learning models for those purposes. In other words, let the learning piece in machine learning do its work.

In order for the models to be completely accurate and help achieve the required goals, you need a very large amount of data.

Customised data

Of course, there is a lot of data available, in some cases even for free. This is fine if you want to build a simple functionality. But for most business changing projects, you first have to feed your systems specialised and customised data sets in order to achieve the desired result. Machine vision is therefore not necessarily a quick fixbut a sustainable fix with sustainable and unrivalled results in the long run.

Would you like to know more about Trendskout, machine vision and computer vision and how AI can help your business grow? Then feel free to contact with us!