From pure divination to AI-based forecasting, predictions for the future have come a long way in the past centuries. In this blog we dive into predictive maintenance. This branch of AI focuses on detecting irregularities or anomalies in order to better estimate the need for maintenance. This is particularly useful in sectors where large machine parks are frequently used. We take a look behind the scenes of the software, its various business applications and the practical implementation in Trendskout.

What exactly is predictive maintenance with AI?

The essence of predictive maintenance or predictable maintenance is simple in design. Complex equipment and industrial machines require regular maintenance. This preferably happens just before the end of the life of the machine or the part to be replaced in question.

In order to guarantee operationality, many machine parts in large production halls are still replaced on a regular basis based on their estimated service life. Often, as a precaution, a much too long buffer time is used and it would be more efficient to be able to intervene predictively.

AI-based predictive maintenance optimizes the timing of maintenance and thus ensures maximum cost savings. We use a number of specific algorithms for this, depending on the type of predictive maintenance that is required in practice.

Classification vs. anomaly detection

Behind the scenes there are two technical solutions to perform predictive maintenance via artificial intelligence. The choice of a specific AI algorithm for data analysis and training depends on the nature of the machines to be monitored. When it comes to devices that often experience breakdowns or downtime, classification is a logical option. If, on the other hand, it concerns devices that only rarely show defects, anomaly detection is usually the better choice.

Detect abnormal events

The inevitable disadvantage of reliable machines is that the data that the machine provides often contains few traces of a concrete failure or indicators that can predict downtime. As long as all components are running smoothly, monitoring systems will indicate few abnormal values for the parameters they are monitoring. In that case, it is also difficult for the AI to learn to estimate which suspicious indications or data anomalies could cause a possible failure of a machine. Fortunately, there are several algorithms specially designed for anomaly detection. Auto encoders, for example. An auto-encoder is a special type of neural network that learns to recognize what exactly can be considered “normal behavior”. Anything that deviates from that standard pattern is by definition an irregularity and cause for alarm. A potential danger of auto-encoders is that because of the way they are constructed, they could also consider more frequent anomalies or anomalies as “normal” if they crop up too frequently. It may therefore be a good idea to remove any excess data from the training data that feeds the algorithm.

Anomaly detection in Trendskout

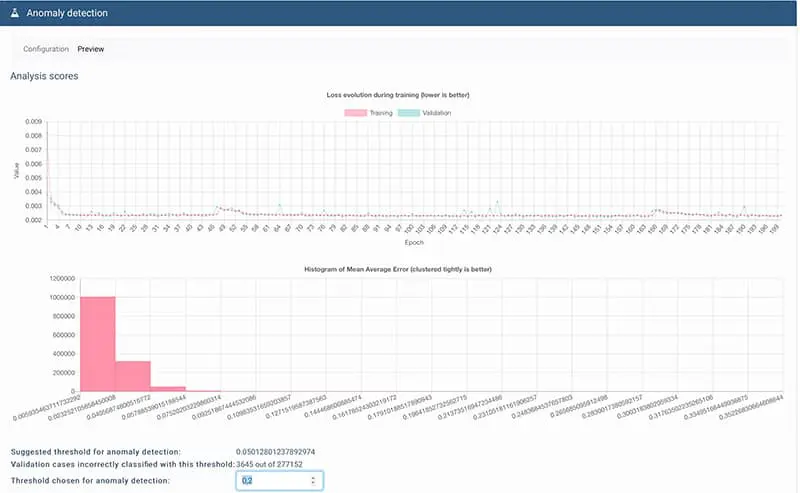

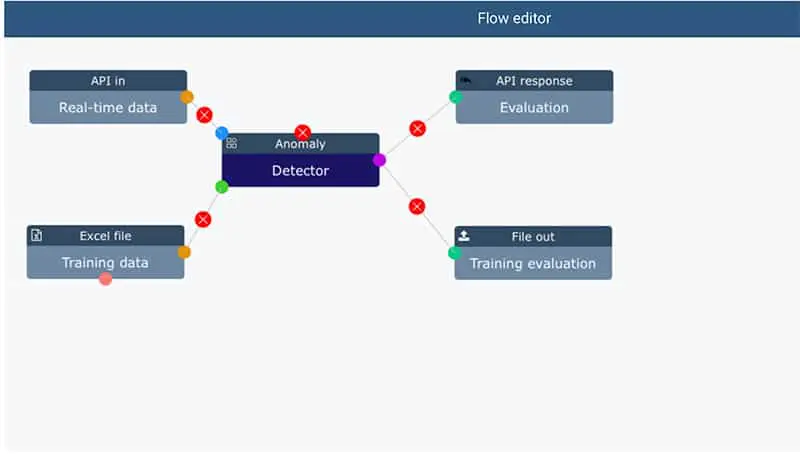

Like all other AI applications, anomaly detection can also be easily set up in Trendskout. The screenshot above shows the Trendskout configuration screen. On the left, we see that both the training data and the actual, real-time data are connected to the neural network of the anomaly detector. The settings screen of the latter looks like this:

The graphs above indicate whether data has been found that deviate from the normal situation and, if so, how large the deviation is. This leads to a mean average error. It is not so much about the absolute values, but about their mutual relationship to each other.

The input field at the bottom of the settings screen shows the threshold or threshold value that the algorithm must use for anomaly detection. The algorithm also automatically determines a suggestion for this.

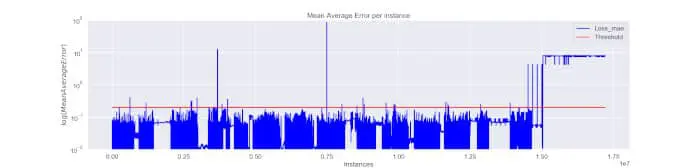

In the image above, the red line represents the threshold. The blue bars are the mean average errors of all registered data. By the way, they are displayed logarithmically to get a better overview. In reality, the anomalous data points are therefore much bigger outliers than one might think at first sight.

Thus, any blue bar above the red line counts as a reportable anomaly for the algorithm. The data is automatically forwarded via an API to the company’s external alert systems or can be added to a text report for further action.

Different algorithms under the hood

The examples above show that anomaly detection does not have to be complicated. As with the other Trendskout analyzes, the platform combines a lot of strong algorithms – including the aforementioned auto-encoders – and the genetic Trendskout algorithm then applies a selection on its own for the best result.

Would you like to apply Predictive Maintenance yourself? Then we are happy to assist you as an AI company. Contact one of our employees without obligation.